- Home >

- 4rconservation

- > Better Management Practices to Conserve Inputs in Container Production

Better Management Practices to Conserve Inputs in Container Production

Better management practices of soilless cultures used in container production can pave the way for efficient use of water and nutrient resources, and higher profit margins. Sustainable production and management practices leads to optimal use of fertilizer and pesticide inputs with lower risks for their loss.

Soilless substrates require conservation strategies

Currently, pine bark is widely used as soilless substrate in container production of nursery crops. Pine bark is porous, inexpensive, stable, and free from pathogens and has low water-holding capacity and low bulk density (Bilderback et al., 2005). It also has low cation exchange capacity (40-75 meq/L) and low anion exchange capacity (near 0 meq/L). However, pine bark requires frequent and extended periods of watering with either overhead sprinklers or drip systems to prevent moisture stress and encourage plant growth. Excessive use of water soluble and slow-release fertilizers in these soilless containers results in significant risk of runoff and leaching of nutrients such as nitrate (NO3 -) and phosphate (PO4 -).

A range of strategies are needed

Most commercial nurseries grow several different species and varieties of ornamentals and fruit trees at different stages of growth and development in containers of varying volumes. All these varying types of plants and containers distributed across the entire field often receive the same formulation and application of fertilizers (i.e., same source, rate, timing and application method). This can result in poor nutrient uptake, non-uniform growth, biotic and abiotic stress, and ultimately crop and monetary losses. Also, local water sources with high alkalinity contribute to the nitrification of ammonium (NH4

+) to NO3

-, which results in higher substrate pH and micronutrient deficiencies that can further limit plant growth.

Water management is key

Container grown plants require significantly more water supply than field grown plants—even during a wet season—because root growth and development is restricted to the container volume irrespective of the amount of shoot growth, limited container volume and water-holding capacity. Additional factors of concern include the prevailing wind direction and its effect on overhead sprinkler systems, and downward movement of water through porous substrates such as pine bark. Appropriate irrigation systems and a field layout composed of different sizes and shapes of plants help deliver water precisely and help to avoid over or under irrigation.

Currently, there are no standard protocols to deliver water to plants in container production systems. At times, water has to be supplied two, three or even four times per day during vigorous plant growth periods due to the low water holding capacity and highly porous nature of substrates used in container production. In most container production systems, a significant percentage (< 80%) of irrigation water provided by sprinkler systems is lost (Fig 1). This is partly due to improper spacing, arranging and management of container plants that does not consider the form of the plant canopy, plant size, leaf orientation, pot size, type of plant (deciduous versus evergreen), growth habit, etc.

Fig 1. Inefficient water management in soilless pine bark substrate affects plant growth. Root growth commonly occupies < 40% of the container volume.

Consider nitrogen loss mitigation strategies

In container production, the total elimination of soil from the substrate mix has been causing loss of both water and nutrient inputs. The addition of 5-10% of clay to the potting media can reduce the risk of leachate runoff while lowering water consumption.

An increase in pH can have a significant effect on NO3 - leaching since nitrification is pH dependent and liming has a significant influence on pH dynamics (Agner, 2003). During any liming operation with either a calcitic (CaCO3) or dolomitic [CaMg(CO3)2] source, the solubility of the added weak bases is the function of substrate pH adjustments.

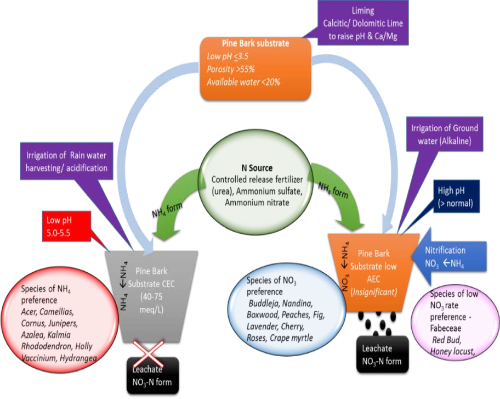

The effectiveness of lime in raising pine bark substrate pH is determined by the material’s source such as calcium carbonate (shell meal or limestone), calcium hydroxide (hydrated lime), or calcium magnesium limestone (dolomite); particle size (course vs. fine) and rate of application (1,200-5,000 lbs per acre). However, liming can create excessively high substrate pH that promotes nitrification and NO3 - leaching and creates micronutrient deficiencies (Sharma et al. 2008). Normally, controlled-release fertilizers are used in container production and they are formulated with urea, which readily hydrolyzes to NH4 +. The risk of loss of NH4 + to NO3 - (or NH3) also depends on the pH of the substrate.

The other contributing factor in raising substrate pH is the source of irrigation water. If alkaline ground water is being used it is important to: a) monitor and manage the substrate and irrigation water pH, b) substitute gypsum (CaSO4) for lime, which does not raise pH but also provides a source of Ca and S, or c) acidify the alkaline water source so that it better suits the crop’s requirement and minimizes nutrient loss (Fig 2).

Fig 2. Flow chart of nitrification and NO3 - leachate runoff in pine bark soilless substrate container production due to poor liming rate, pH and alkalinity factors, and species preference for inorganic N forms.

To improve N uptake in container grown plants, it is best to first organize the plants in the field according to the species’ preference for inorganic N source (i.e., NH4 + or NO3 -). Then other factors such as substrate pH, water requirement (i.e., high/moderate/low), species (i.e., genus family) association with symbiotic microbes (i.e., rhizobium/mycorrhizae), and growth habit (i.e., slow versus vigorous) should be considered (Table 1).

Table 1. Species specific requirement of N source, pH, Ca source, and irrigation water quality.

| Selected species | Nitrogen source |

Preferred pH acidic/basic |

Liming source CaCO3 or CaMg(CO3)2 |

Irrigation water quality |

|

Species preference for NH4-N 1. Acer spps (Acer rubrum, Acer palmatum), 2. Blueberry (Vaccinium corymbosum), 3. Camellias (C. japonica, C. sasasqua), 4. Dogwood (Cornus alba), 5. Hydragea (Hydrangea paniculate), 6. Junipers (Juniperus chinensis), 7. Kalmia (Kalmia latifolia), 8. Rhododendron spp. |

> 75% NH4 or Urea & < 25% NO3 |

5.0 - 5.5 | CaSO 4 |

Acidified water or

rainwater |

|

Species preference for NO3-N 1. Butterfly bush (Buddleia davidii), 2. Nandina (Nandina domestica), 3. Boxwood (Buxus sempervirens), 4. Peaches (Prunus persica), 5. Fig (Ficus carica), 6. Crape Myrtle (Lagerstroemia Hybrid) |

> 75% NO 3 and < 25% NH 4 or Urea | 5.8 - 6.8 | Calcitic (CaCO 3 ) or Dolomitic lime [CaMg(CO 3 ) 2 ] | Neutral/Alkaline water or rainwater. Do not acidify the water |

|

Species preference for low N for symbiotic microbes (Rhizobium) 1. Redbud (Cercis canadensis), 2. Honeylocust (Gleditsia triacanthos) |

75% NO3 and 25% NH4/Urea Mix 10% of soil to soilless substrate for rhizobium/mycorrhizae |

5.8 - 6.8 | Calcitic (CaCO 3 ) or Dolomitic lime [CaMg(CO 3 ) 2 ] | Neutral/Alkaline water or rainwater. Do not acidify the water |

The availability of water is limited in container grown plants compared to field grown plants. The percentage of available water is < 22% of container capacity and it declines overtime with the decomposition of the substrate. Unwanted water and nutrient loss are of environmental concern for the nursery industry. Therefore, cultural practices that conserve water and capture and recycle runoff will promote and strengthen the sustainability of the nursery industry. Research followed by demonstration and outreach programs to nursery growers on the impact and strategies of minimizing NO3

- and PO4

- leachate run-off, and updates of the cultural practices that are specific to each species can reduce the loss of crop inputs and conserve water.

Consider the 4R nutrient stewardship concept

Efficient container production technologies that demonstrate 4R, or the 4 ‘rights’, of nutrient stewardship (i.e., using the right nutrient source, at the right rate, time, and place) will have a direct impact on nursery crop production both in terms of moisture and nutrient conservation and profitability in Tennessee and other southeastern States of the USA.

By Dr. Dharma Pitchay is Assoc. Professor, Department of Agricultural and Environmental Sciences College of Agriculture, Tennessee State University, Nashville, Tennessee, USA. e-mail:

dpitchay@tnstate.edu

Further reading

Agner, H., 2003. Denitrification in cultures of potted ornamental plants. Genehmigte Dissertation von Dipl. Ing. Agr., der Universitat Hannover, Hannover.

Bilderback, T.E., S.L. Warren, J.S. Owen, Jr., and J.P. Albano. 2005. Healthy substrates need physicals too! HortTechnology 15:9-13.

Jackson, B.E., R.D. Wright, J.F. Browder, J.R. Harris, A.X. Niemiera, J.M. Tiedje. 2008. Effect of Fertilizer Rate on Growth of Azalea and Holly in Pine Bark and Pine Tree Substrates Ecology of denitrification and dissimilatory nitrate reduction to ammonium, Hortscience 43(5):1561–1568.

https://doi.org/10.21273/HORTSCI.43.5.1561

Sharma, J., P.C. Wilson, T.H. Yeager. 2008. Remediation of runoff: Options for container plant nurseries. ENH1088: University of Florida Cooperative Extension Service.